Central utility systems generate and distribute the cooling, heating, and power that energize various buildings and processes. While campuses, shiny buildings, and historic structures are visible, the central utility plant is the unseen backbone that keeps them functional. At Loring, we have been involved in many central utility and infrastructure projects, including:

- Chiller plants

- Boiler plants

- Thermal storage systems including ice and water

- Battery Storage systems

- Cogeneration systems

- On-site generation

- Microgrids

- Electrical system upgrades

- Renewable energy systems including biogas, biomass and solar

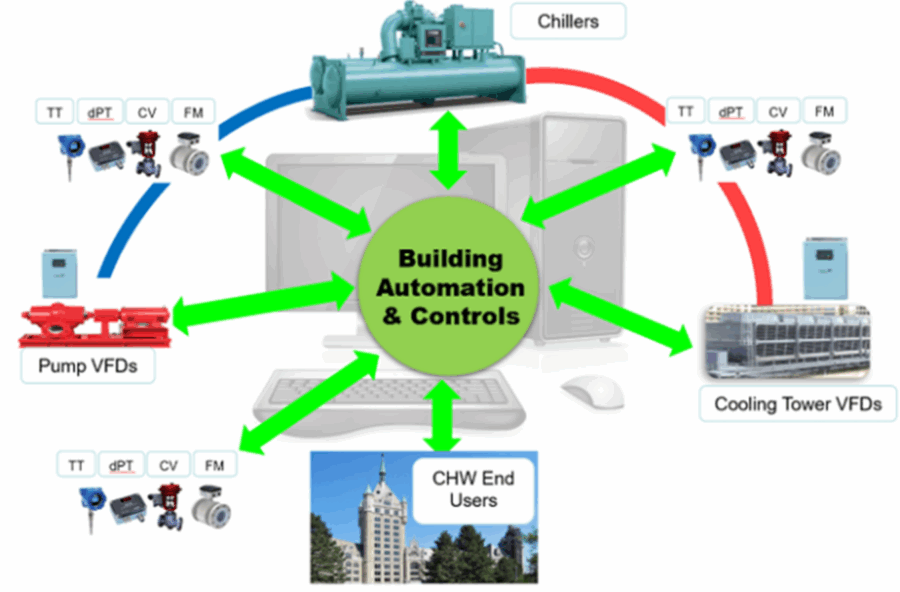

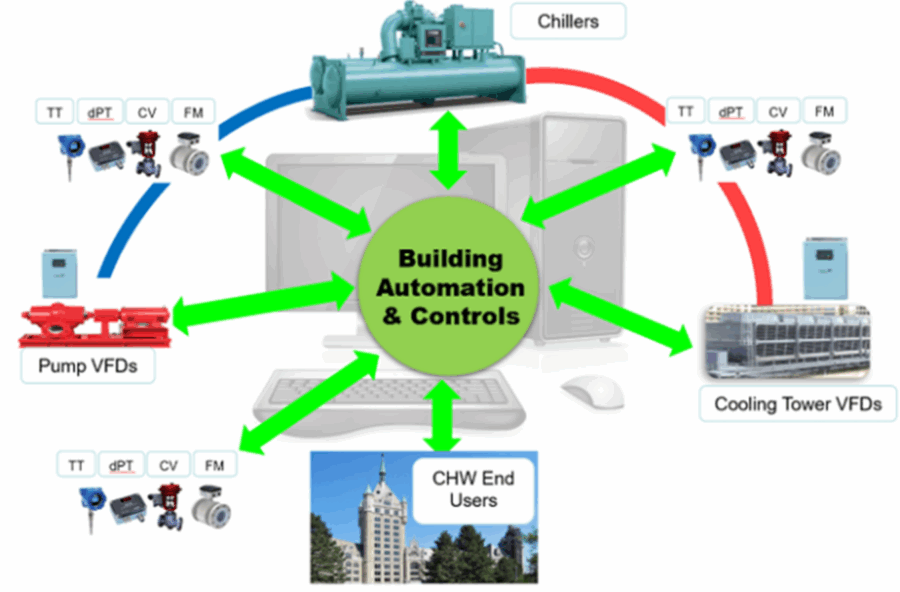

The energy sector’s evolution requires a new approach to how we generate, distribute, and use power. While transitioning to technologies like electrification, heat pumps, and energy storage, existing systems must remain efficient. The key to this is optimizing system-wide performance, not just improving individual components. For example, a central plant’s efficiency relies on the integrated operation of equipment like chillers and cooling towers. Providing a centrifugal chiller with colder condenser water, or tailoring energy distribution to exact demand, provides significant energy savings that component-level improvements alone cannot achieve.

Case Study: Northern Westchester Central Chilled Water Plant

Every project has unique in terms of its requirements, challenges and deliverables. Loring recently completed a 4,000 Ton central chiller plant project for Northern Westchester Hospital.

- Plant size: The existing central plant consisted of 1,800 tons of chilled water system. Due to expansion of the hospital and repurposing of some of the building areas, the long-term need for the hospital was estimated to be 3,000 Tons. The facility selected the option of utilizing three electric centrifugal chillers and two steam absorption chillers. This increase in the capacity and development of the central plant had to be incorporated in the same footprint of the existing plant. Along with this, the hospital had to remain fully functional with minimal downtime. The hospital’s existing central plant, with 1,800 tons of chilled water capacity, required expansion due to growth and building repurposing. The long-term need was projected at 3,000 tons. The solution chosen involved integrating three electric centrifugal chillers and two steam absorption chillers within the existing plant’s footprint, all while maintaining full hospital functionality with minimal downtime.

Northern Westchester Central Chilled Water Plant

- Hydraulic Analysis: Loring performed detailed hydraulic analysis for distribution of chilled water throughout the campus. The evaluation was performed for the short-term needs, intermediate term needs and long-term needs of the facility. The facility had indicated that they have trouble getting chilled water in certain spaces of the hospital. The hydraulic evaluation revealed the bottleneck in distribution system, chilled water pump head requirement and remote locations for pressure sensors.

- Change of chilled water Delta T: Due to increase in the chilled water capacity, the chilled water flow increased substantially. With the main distribution pipes running in a tunnel under the building, replacing this would have become a very intrusive process to a fully functional hospital during construction. As a part of the new plant design, the chilled water delta T was increased thereby allowing us to utilize the existing distribution piping network.

- System efficiency: Incorporating magnetic bearing centrifugal chillers provided substantial efficiency improvement if the condenser water temperatures can be depressed to as low at 40 deg F. The absorption chillers need to maintain condenser water temperatures in excess of 75 deg F to avoid crystallization. To maximize the efficiency of the system, condenser water controls were separated to meet the needs of each system thereby providing optimum efficiency for each system. Due to efficiency improvements, the facility received rebate of over $400,000 from local utility.

- Chilled water temperature: The facility is located in a valley and experiences high humidity ambient conditions. Due to the nature of the application, operating rooms (ORs) and intensive care units (ICUs, NICUS) are sensitive to humidity requirements and any change in chilled water temperature creates unfavorable conditions in these spaces. As a part of the central plant project, new sequence and systems were implemented where in the facility always receives set chilled water temperature. During start-up and shut down of chillers, automatic systems modulate to ensure that chilled water leaving the central plant is always maintained at set point.

BAS System Screen

- Automatic Central Plant Controls: New building automation system (BAS) incorporates fully automatic functioning of chillers and associated accessories. When the demand for cooling changes, permissive are displayed on the screen to either start or stop a chiller. Based on the operating executive’s preference for the next chiller to be turned on or off, associated chilled and condenser water pumps, cooling towers are automatically turned on or off.

Northern Westchester Hospital Steam Absorption Chillers

Get In Touch

For more information on Central Utilities, contact Nitin Pathakji, CEM

Vice President, Central Utilities

npathakji@loringengineers.com